ZPRACOVANIDIAMOND

Diamond processing

Diamond processing

The price of a diamond has been directly proportional to its weight for hundreds of years. Jewellery was set only with rough diamonds. It was the only way because nobody was able to cut and work a diamond. It changed in the 14th and 15th century. The Belgian, Lodewijk van Bercken discovered the process of cutting one diamond by using another. Nowadays a common rule is that a diamond loses approximately half of its rough weight before it is set into jewellery.

A masterpiece of skill

A rough diamond looks like an uninteresting piece of glass. Only after processing and grinding the facets will it unfurl its glory and glitter. A thorough study of the rough stone is necessary to produce the biggest possible diamond with the least amount of impurities. This job requires great experience and knowledge of diamond crystallography and of the possible impurities that may be in diamonds. What final shape will the stone have?

How does a diamond look like?

The most common cut is the round brilliant. A typical round brilliant has 57 facets: table (big central facet), 32 facets on the crown (the top part of a brilliant cut) and 24 facets on the pavilion (the lower part ending in a tip). It loses more than half of its original weight through cutting.

Processing diamonds step by step

Marking

First, the specialist analyzes the rough diamond and decides how the diamond will be processed. Then the diamond is marked, cut and polished. Each diamond is unique and the whole procedure is specific for every particular stone. The yield depends above all on the shape and quality of the rough stone.

Cleaving

Cleaving is a method of splitting the stone in two or more parts with a single hit along the cleavable lines –that is to say only in a certain direction. This technique was used in India hundreds of years ago and it required great skill. Cleaving is always done parallel in the direction of the grain of the crystal. The stone is fastened in a wooden holder and opposite it another holder clamps a second sharp diamond to make a slit into the stone. It is then split after hitting a tool of steel with a hammer.

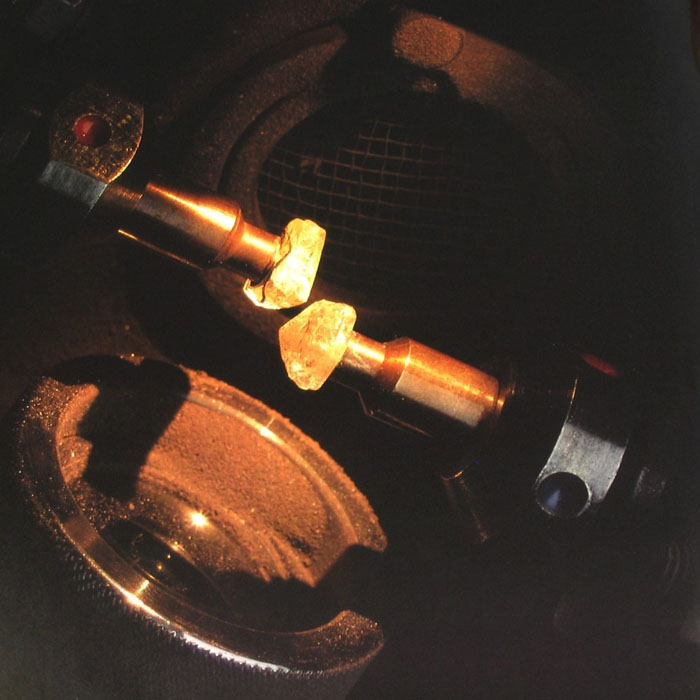

Sawing

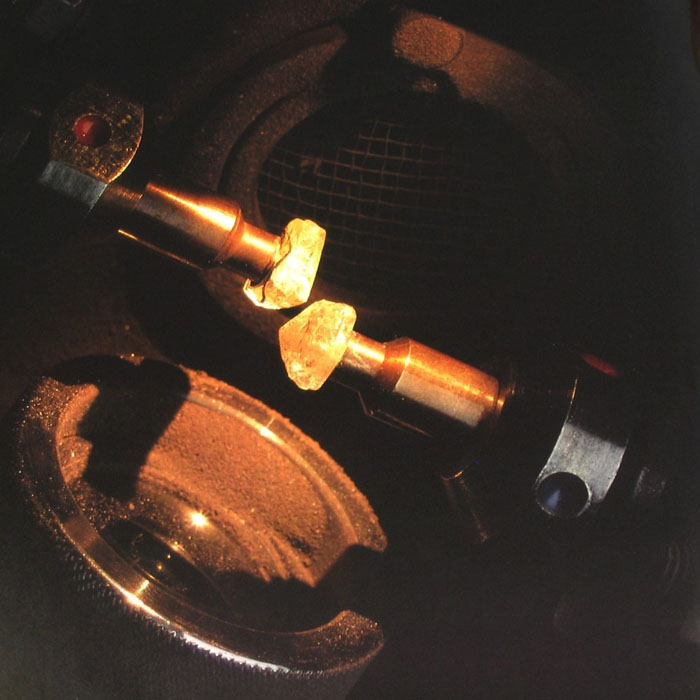

Sawing is carried out against the direction of the crystal grain. The diamond is fastened to a copper head using a special mixture of gypsum and limestone. Once the mixture hardens the head is clamped to the cutting machine. The stone is sawn by an extremely thin disk which is covered by oil and diamond powder and reaches a rotation speed of between 15.000 and 17.000 rpm. The best speed of sawing is approximately 1 mm per hour. Sawing of large stones can take up to several weeks.

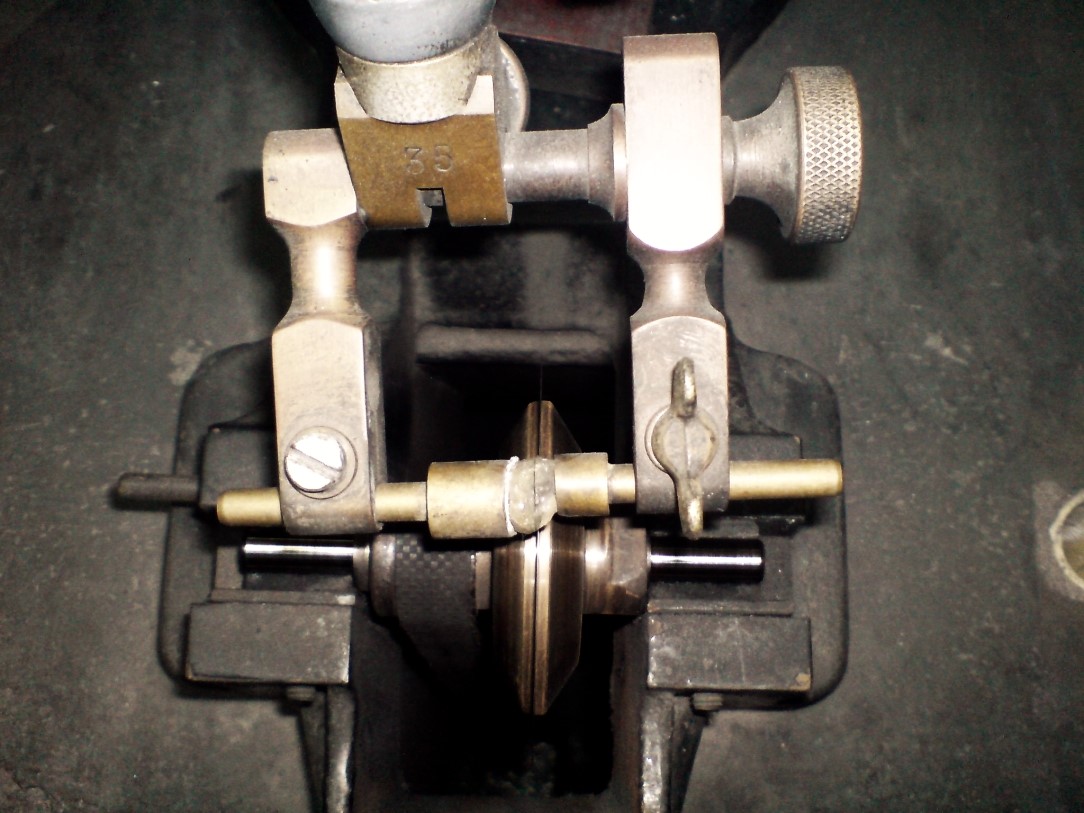

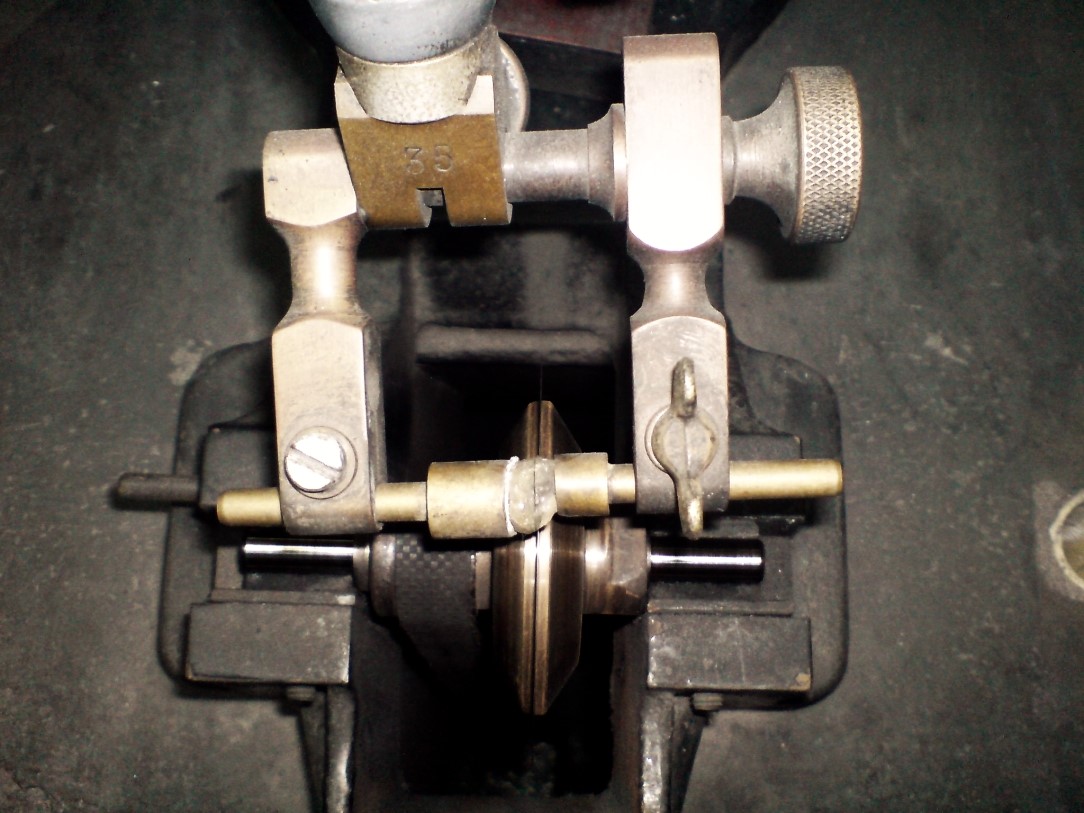

Bruiting

A diamond gets its future shape by bruiting a cleaved or sawn stone. The traditional method is again mounting the diamond to the head of a lathe. By means of another stone mounted opposite it, bruiting is carried out whereby the stone obtains its round shape.

Cutting

It is the process of creating facets on the stone. A diamond is clamped into the special pliers of the cutting machine, called a quadrant, at a precisely adjusted angle against the cutting disk. The cutting disk is made of steel and it is covered with a mixture of oil and diamond powder.

Tradition against modern

Although manual methods are still used, modern methods also play a very important role e. g. laser is used to mark the stone before cleaving, sawing and shaping. It is not necessary to concentrate on the crystal growth lines when using a laser but a diamond loses slightly more of its weight compared to older mechanical methods. In spite of the undeniable advantages of modern technology, human skill plays an irreplaceable role in the end of this process, which produces a fascinating cut jewel out of raw material. Several people always participate in the creation of one cut diamond. Usually one person makes the cutting design, another does the sawing, another bruiting and then at least two cutters follow, a so-called blocker and brillianter. Small diamonds, so called “melées”, are literally cut in bulk. Each facet type is cut by another cutter. These melée diamonds are cut exclusively in India and China, bigger diamonds in Belgium, Israel and USA.